In this part of the article we will describe further types and ways of making architectural models in order to present even better the possibilities of making models.

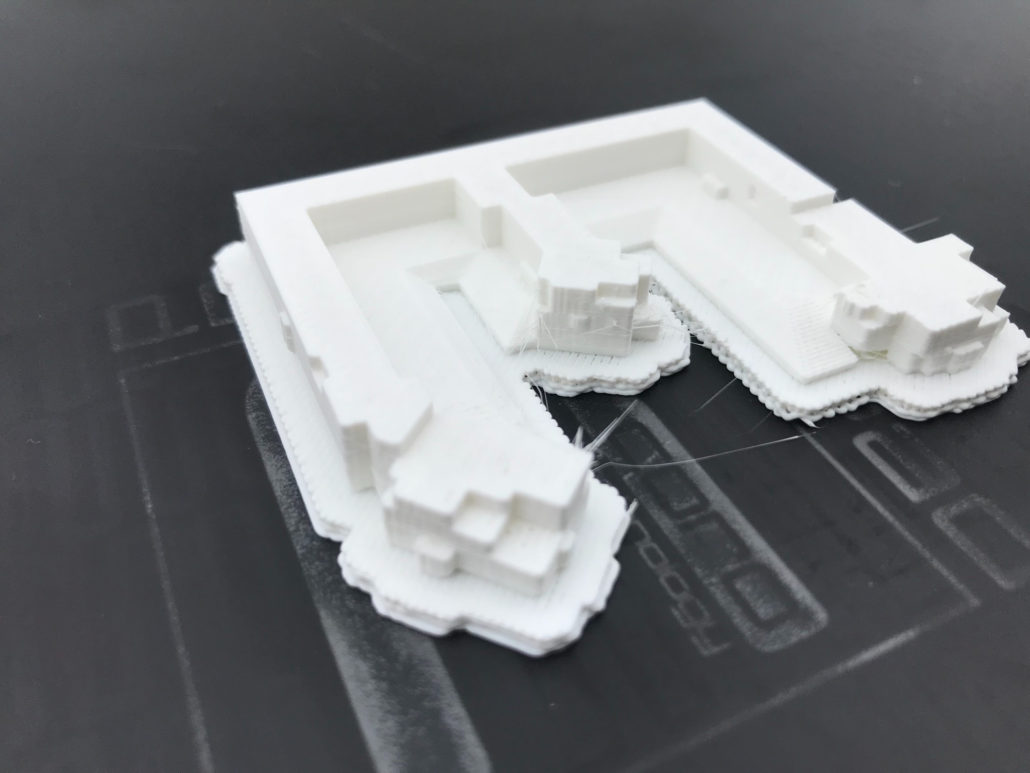

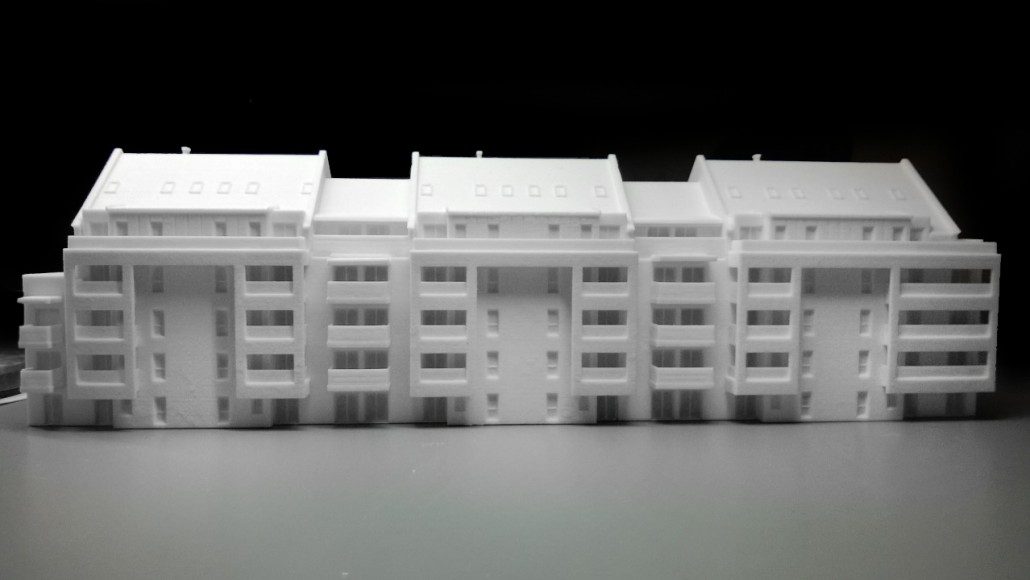

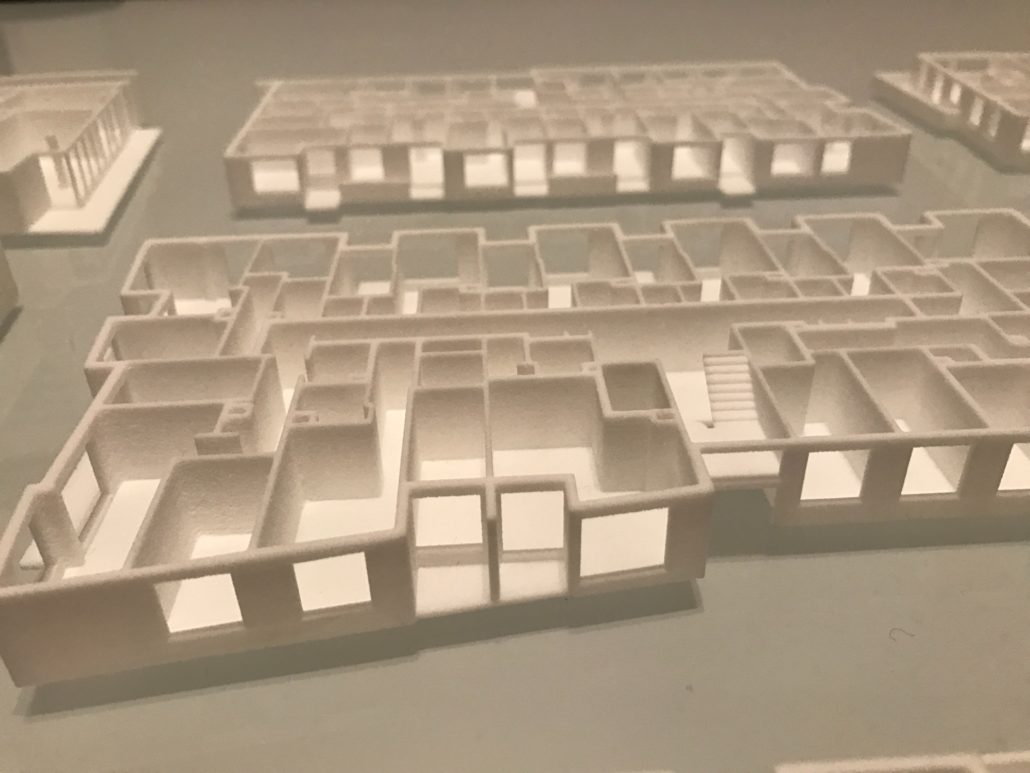

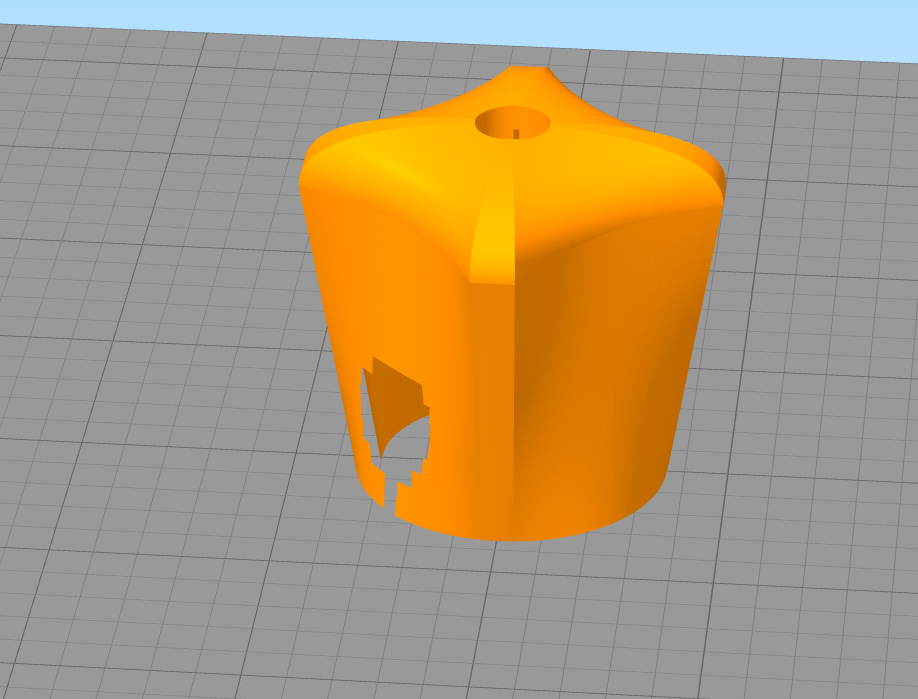

Scale models from FDM (Fuse deposition modeling) 3D printing

3D printing technology is becoming more and more popular during building design. It allows for a quick and easy way to present the concept of the model and transfer it to reality. Due to the low cost of 3D Printing (f.ex. FDM), we can afford to make various concepts and choose the best one.

Standards of scale: 1:50/1:87/1:100/1:120/1:220

Main features: Details limited by the features of 3D FDM printing technology. Visible layers of 3D printing and connections between elements.

During 3D FDM printing, the supports are created after removal of which the traces remain visible. Filling and painting of models is possible.

Technology of execution: FDM 3D printing. Limiting the model size to the working chamber of the machine.

Materials: PLA, ABS, HIPS – plastic for FDM 3D printing

Colouring: Monochrome or painted models after printing according to the given color scheme.

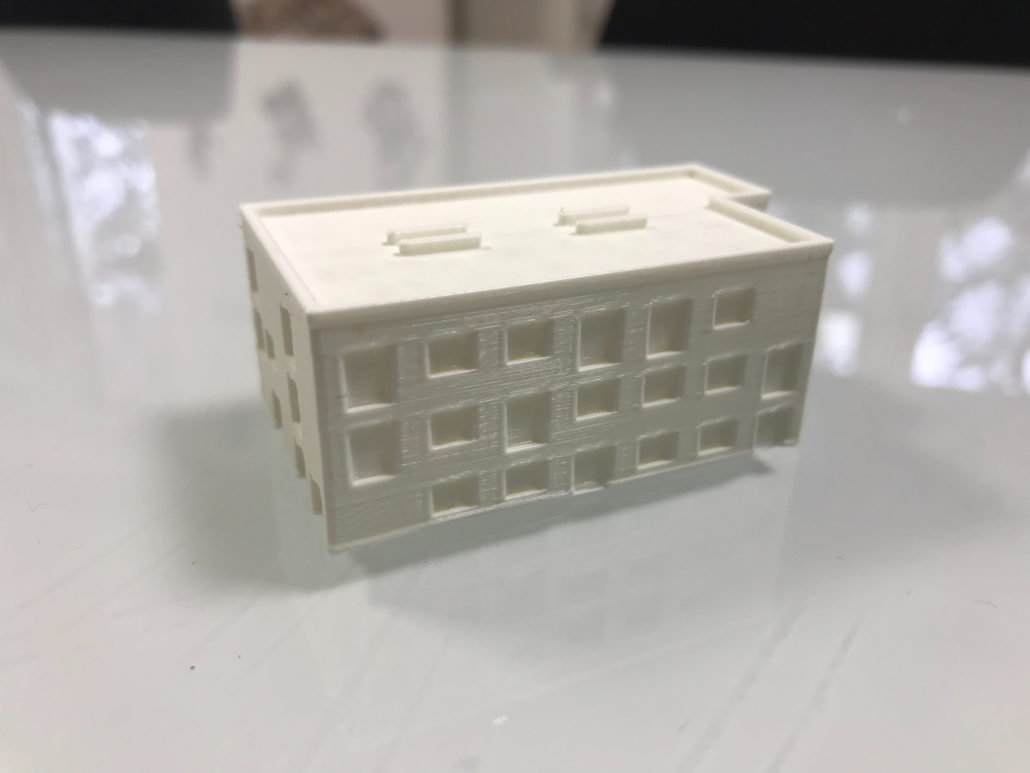

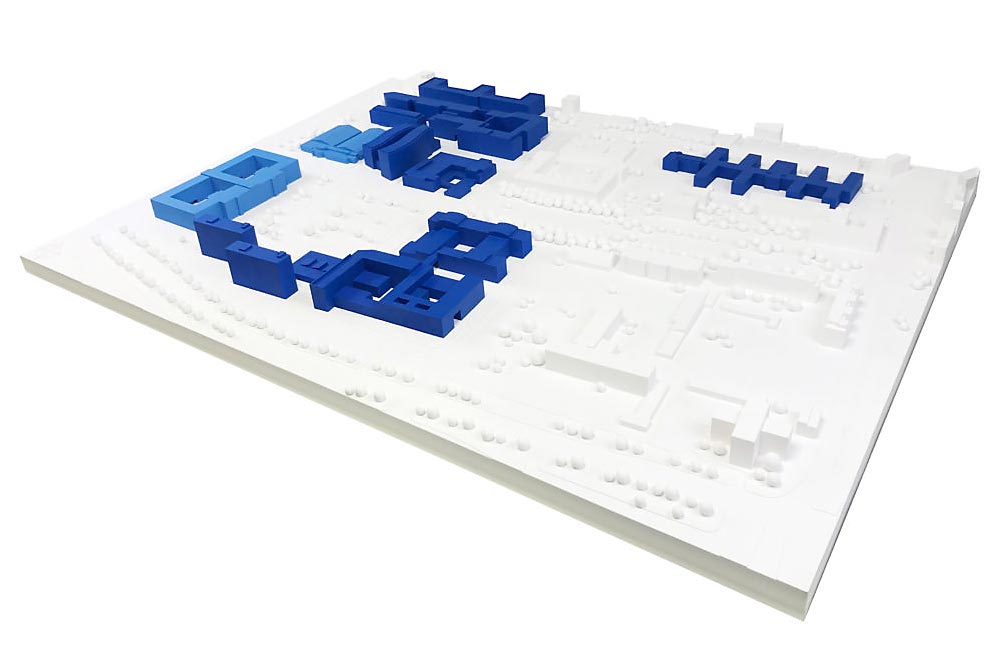

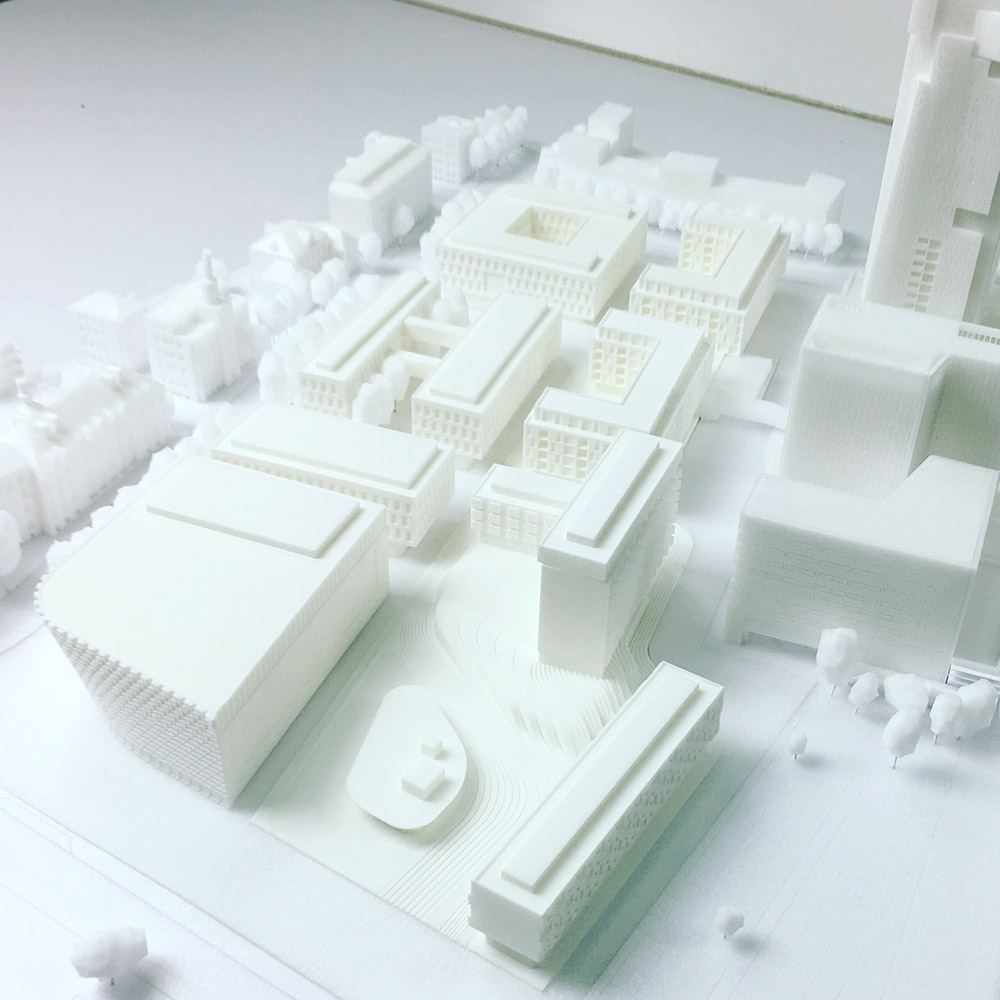

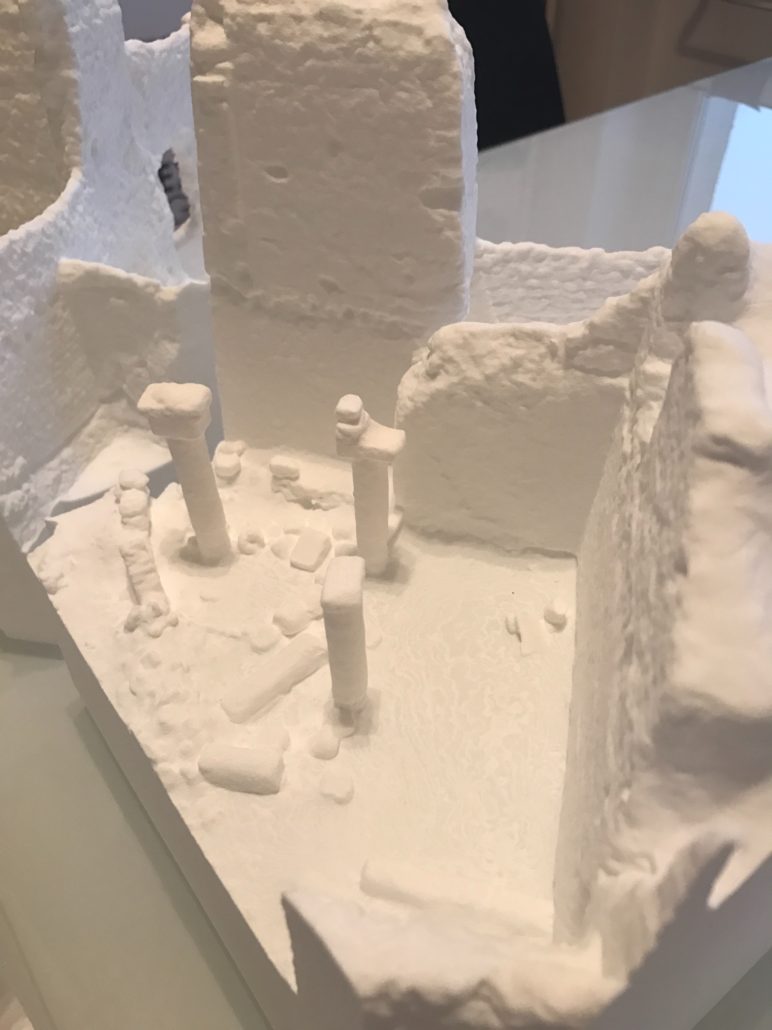

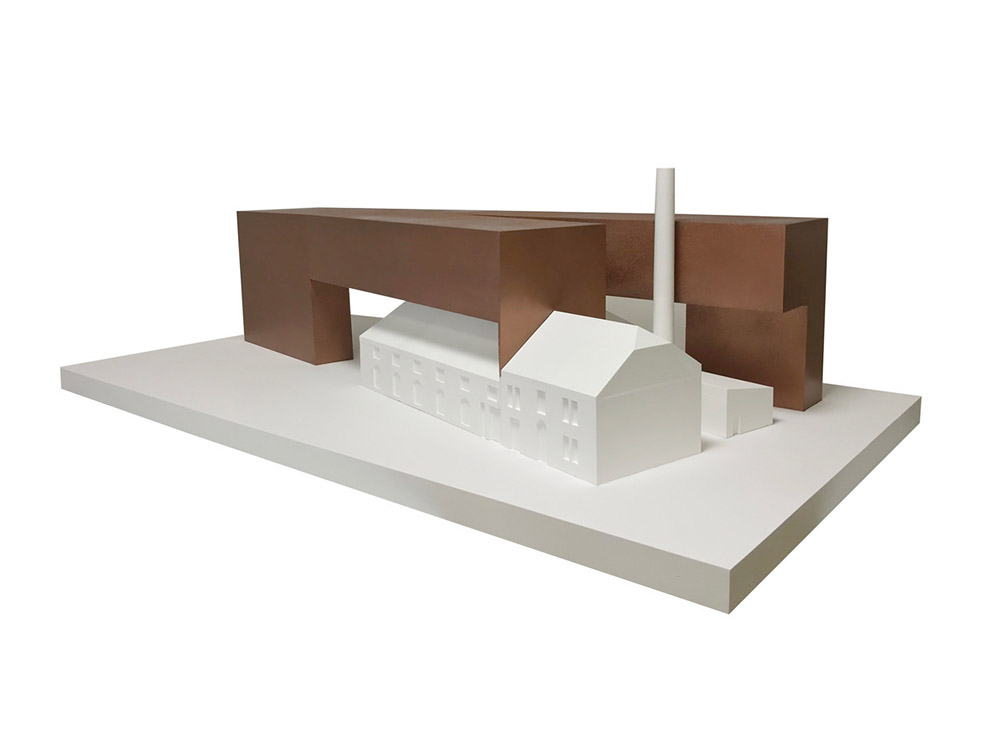

SLS (Selective laser sintering) 3D printed mock-ups

SLS 3D printing technology gives more possibilities through the production process itself. The models print in a chamber filled with PA (Polyamide) powder, thanks to this solution the models do not need any supports. This way we can achieve even the most complicated geometries.

Standards of scale: 1:87/1:100/1:120/1:220/1:500/1:1000

Main features: Details limited by the features of 3D SLS printing technology. Good representation of the geometry of the model. Works well for complex geometries and urban models.

Materials: Polyamide, white

Colouring: Monochrome or painted models after printing according to the given color scheme.

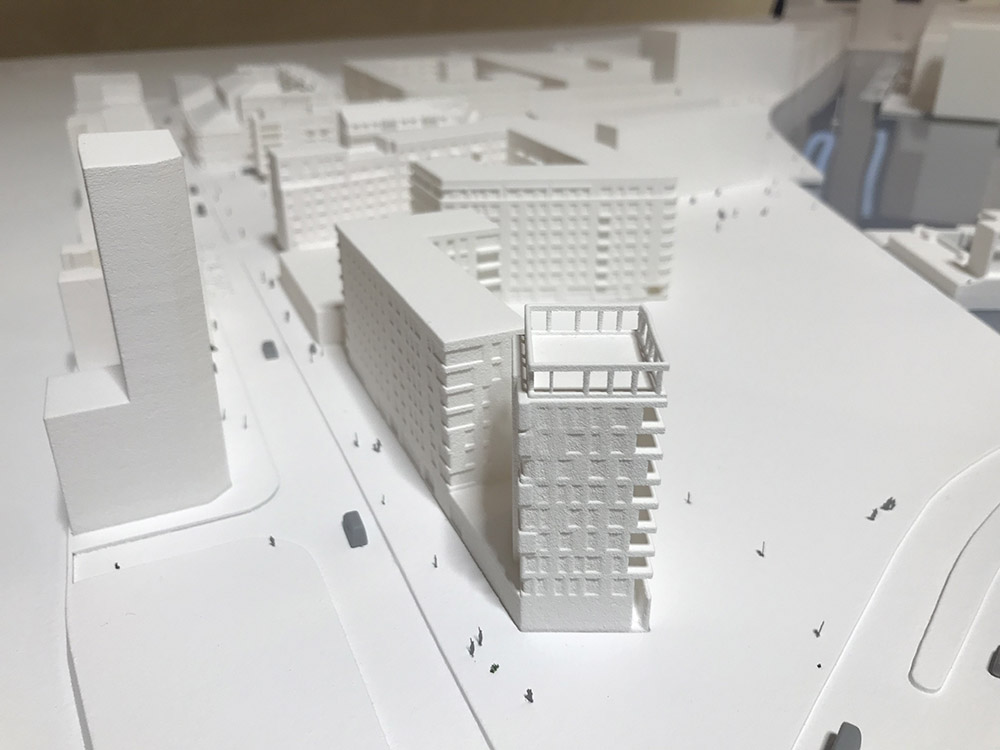

Scale models made in DLP and SLA 3D printing technology

3D resin technology prints give the best surface quality of the model and most importantly a very good detail. This allows to print 3D very small elements.

Standards of scale: 1:220/1:500/1:1000/1:2000

Main features: Very accurate models based on digital files. Good representation of the geometry of the model. Works well with small detailed models and urban models.

Technology :DLP and SLA 3D printing. Limiting the model size to the machine’s working chamber.

Materials: Resin

Colouring: Monochrome or painted models after printing according to the given color scheme.

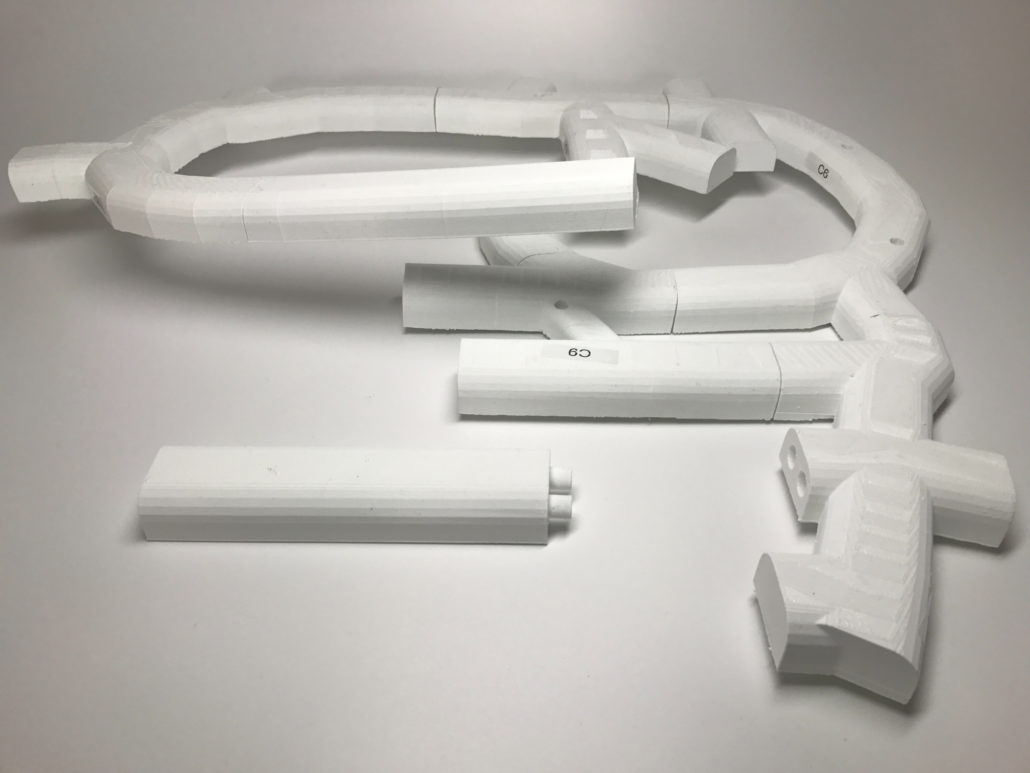

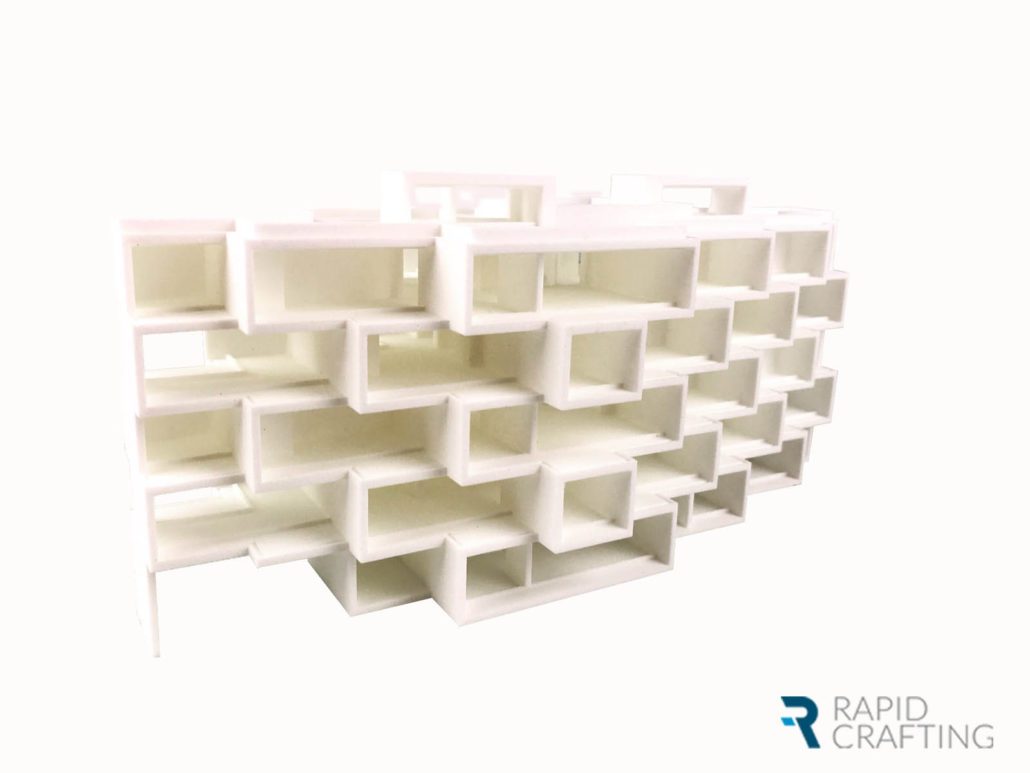

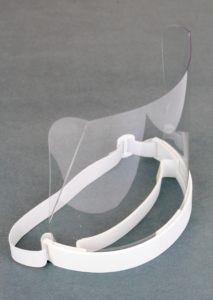

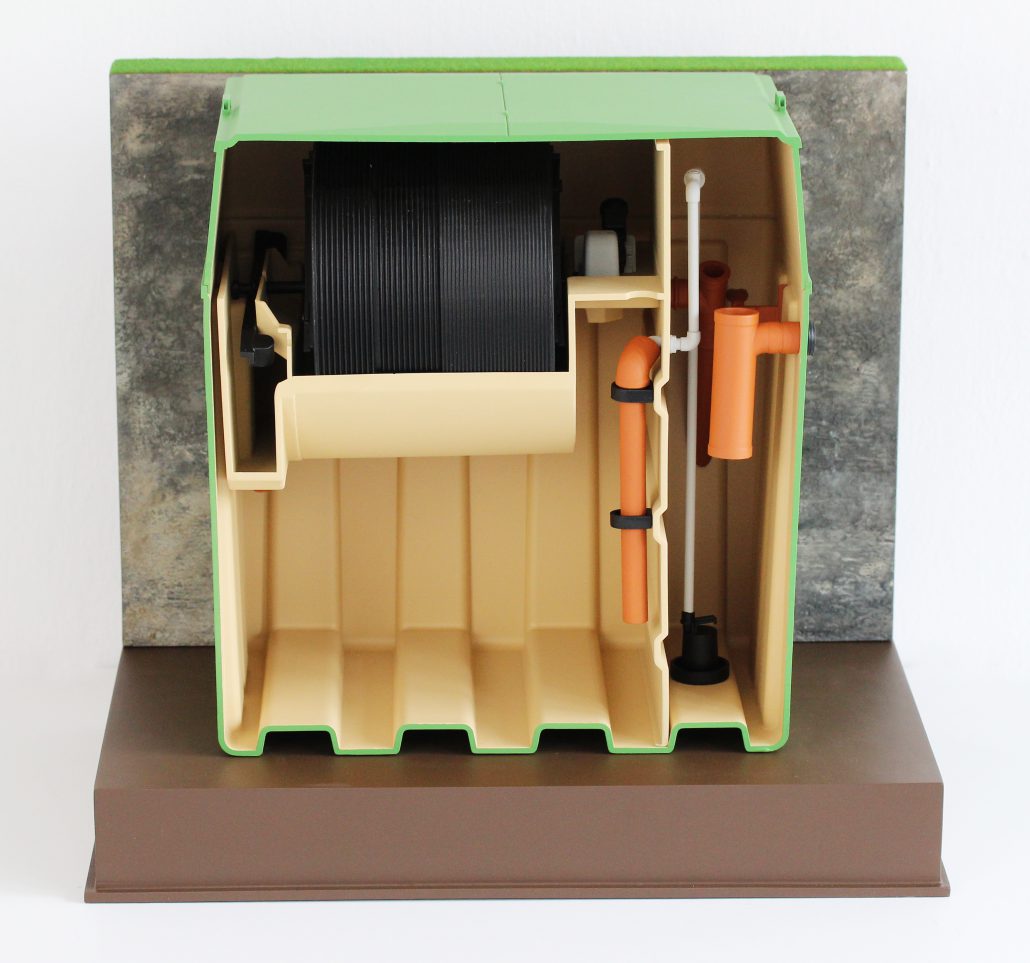

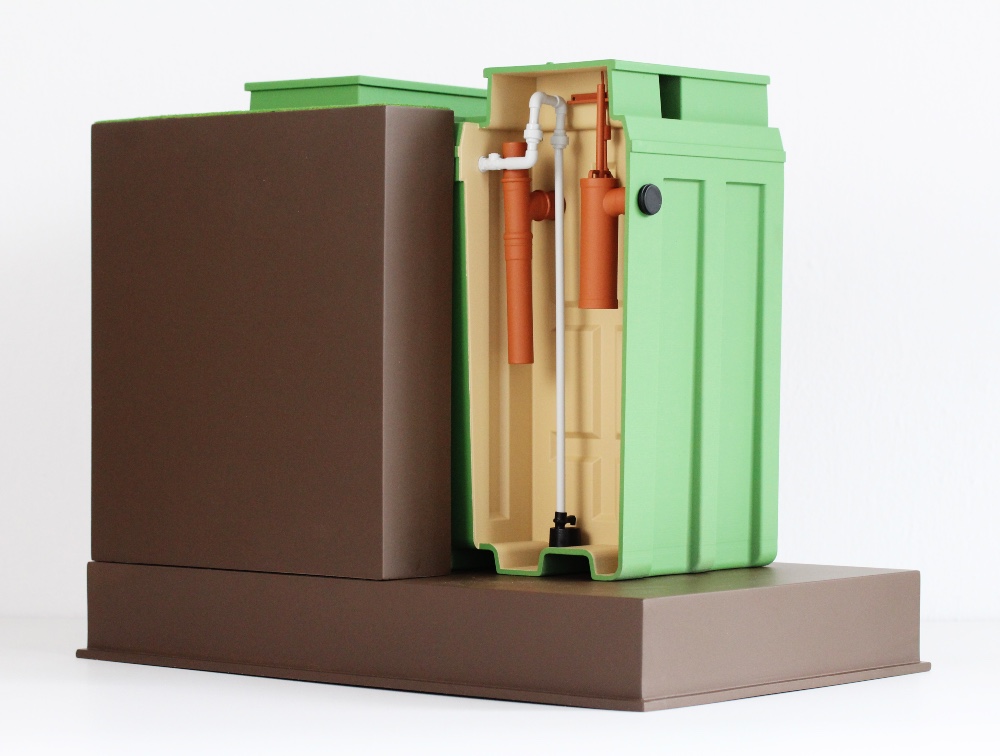

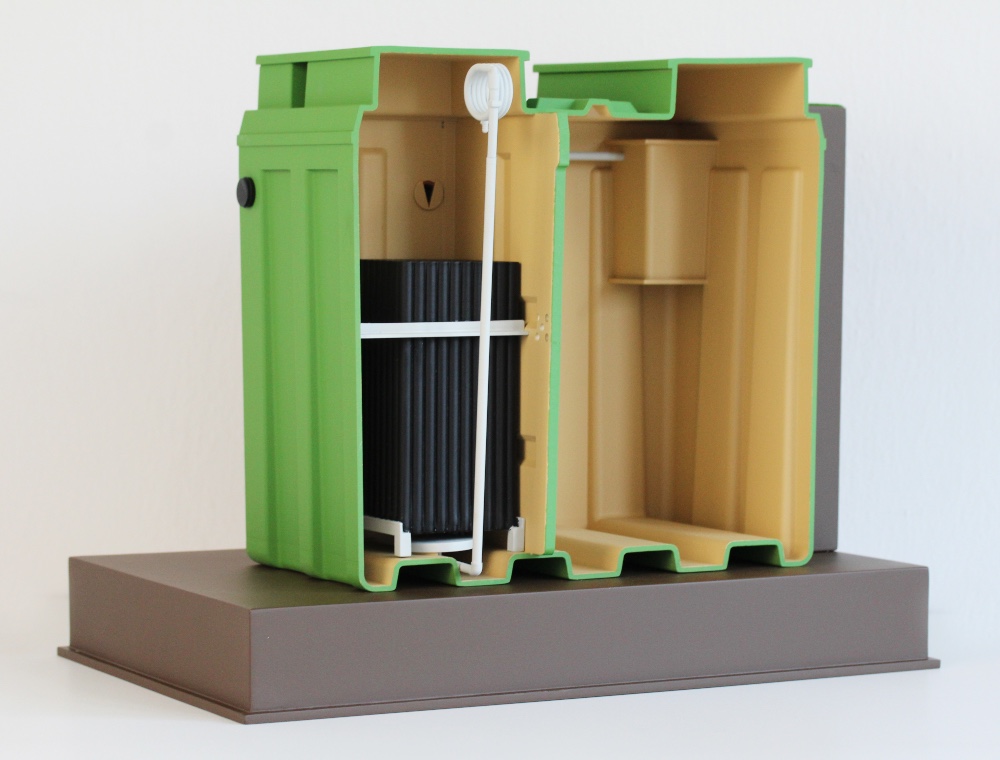

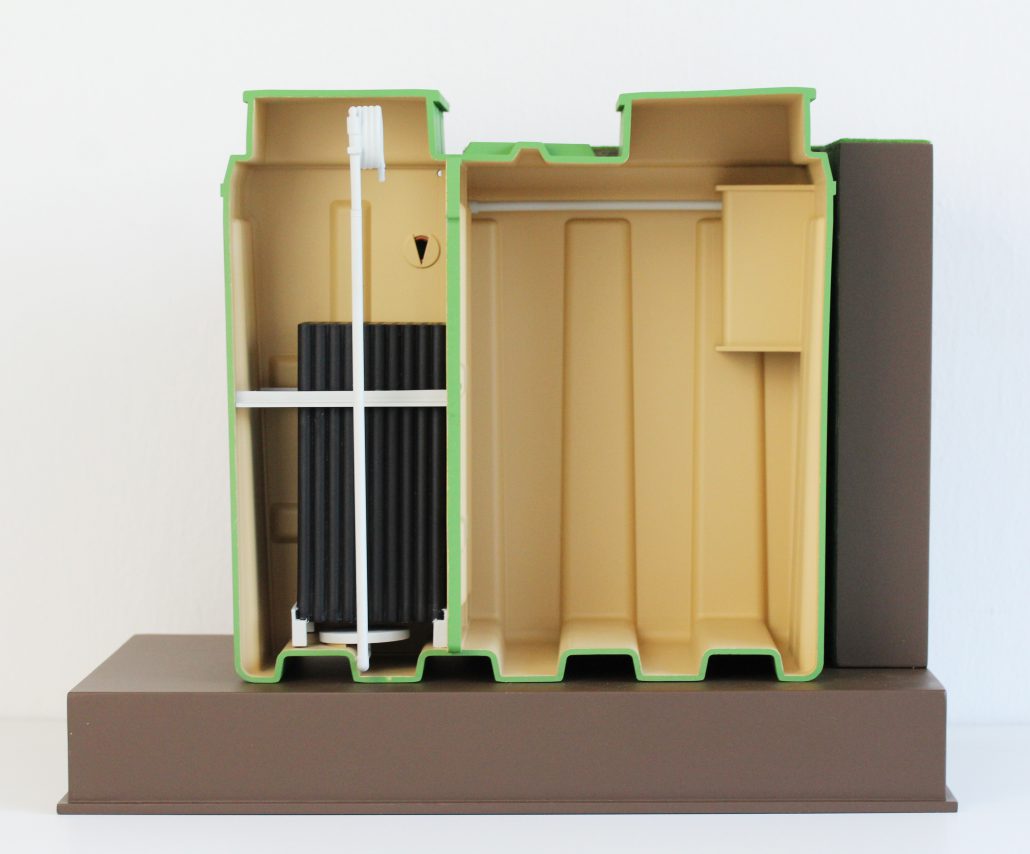

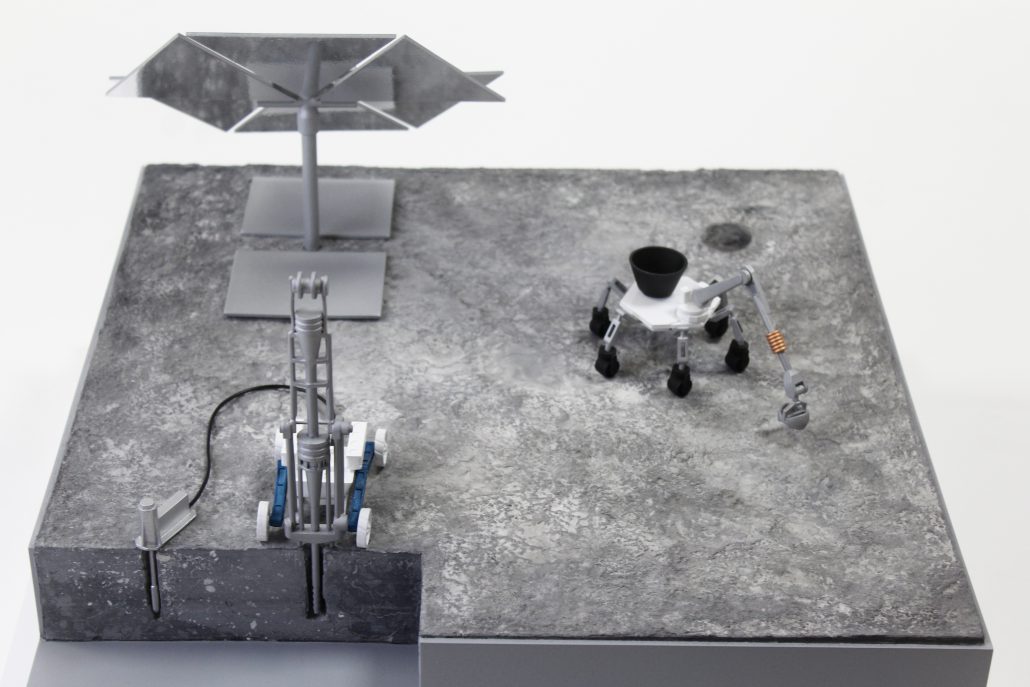

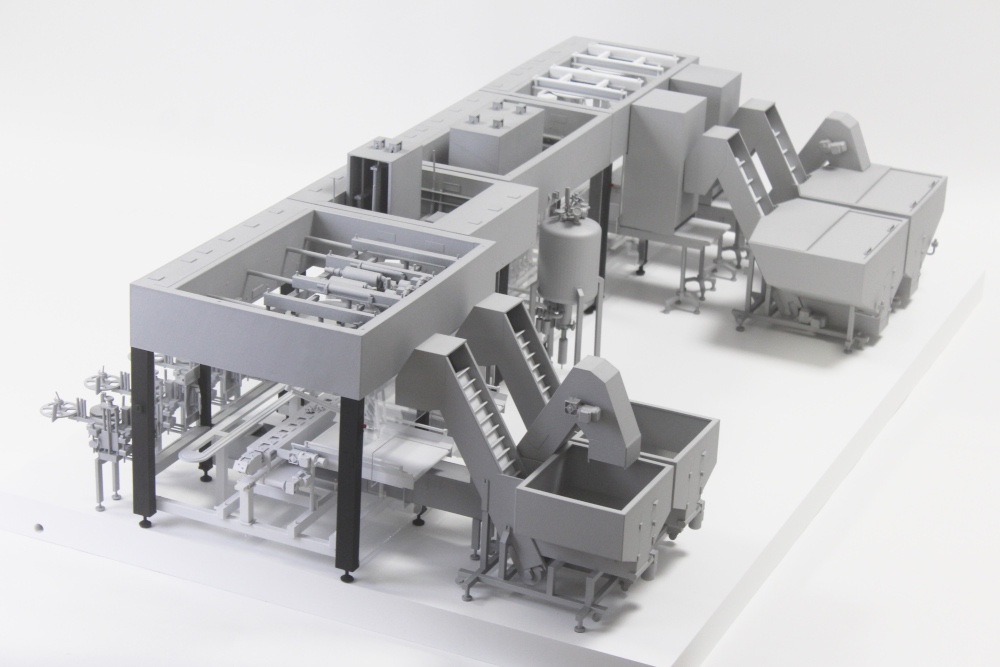

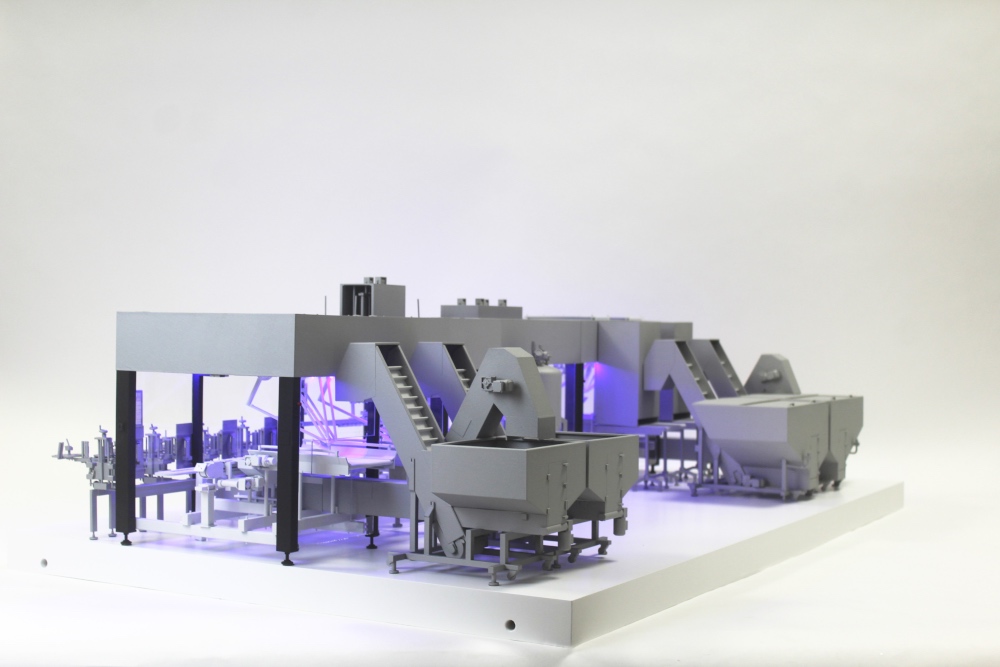

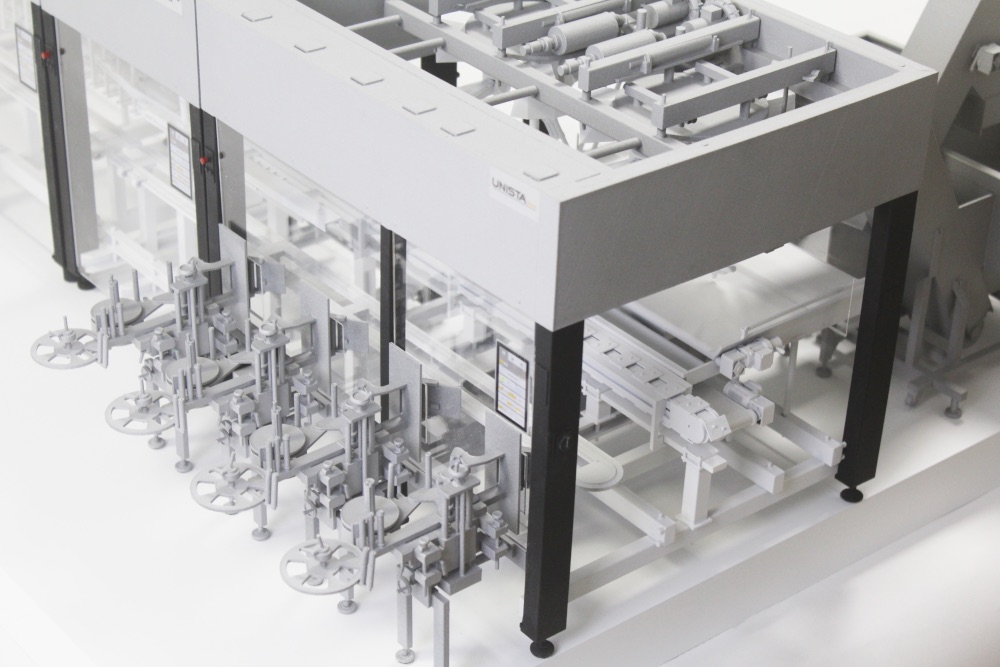

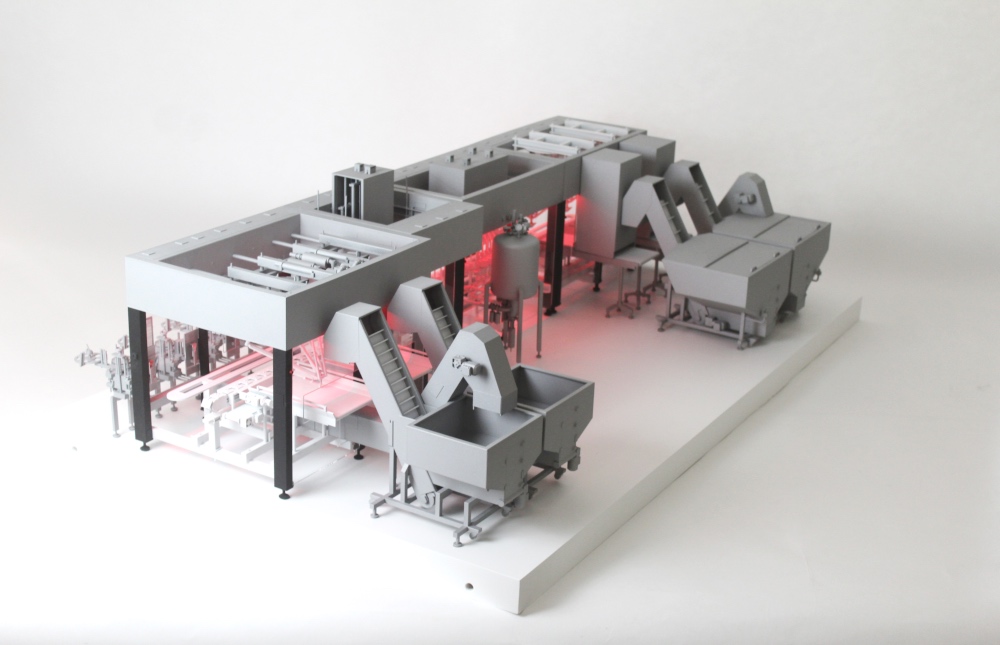

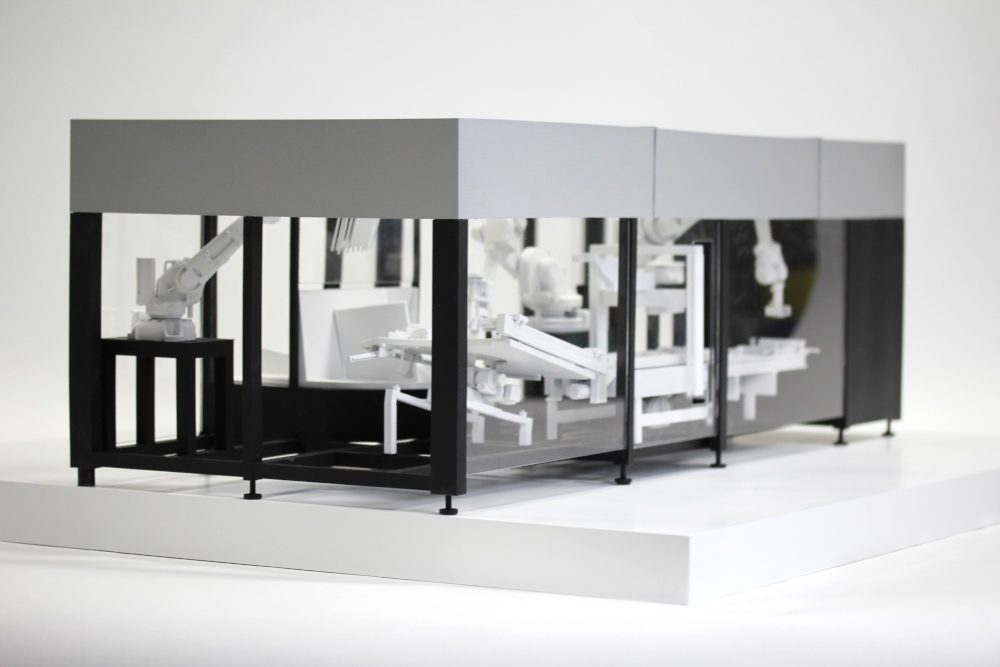

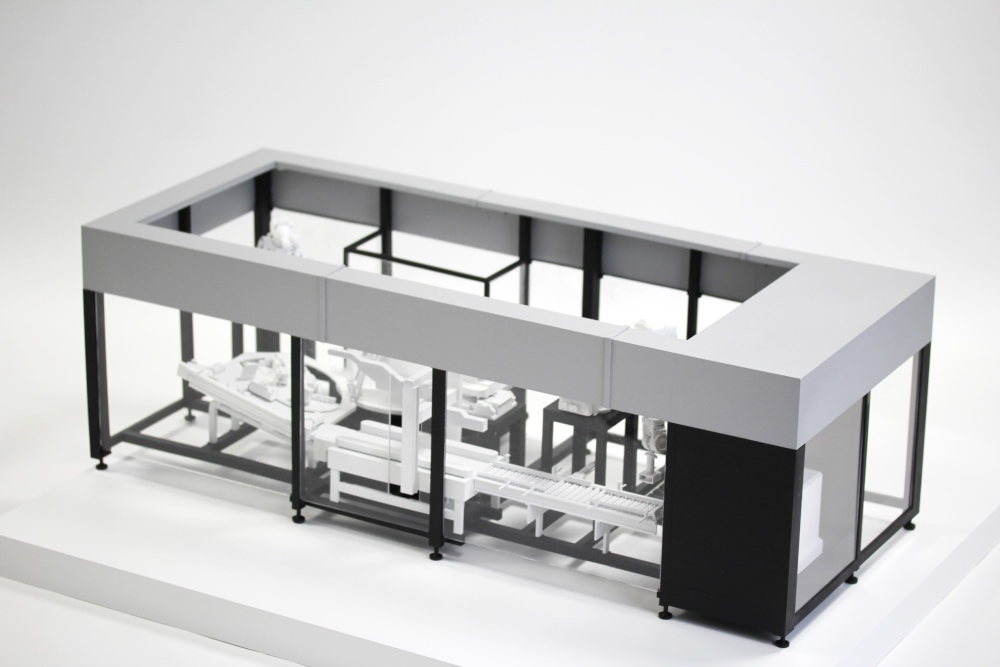

MJP (Multi Jet printing) 3D printed scale models

MJP technology is a 3D printing technology from resin, however, unlike the DLP and SLA process it does not produce standard supports, but uses a special washable supporting material. Thanks to this solution we can achieve very complex structures and very small elements. Often we produce elements for mock-ups which we are not able to produce using conventional methods.

Standards of scale: 1:87/1:100/1:150/1:220/1:500

Main features: Very accurate models based on digital files. Good representation of the geometry of the model. Soluble supports allow to make very complicated geometries.

Mainly used for making small elements in mock-ups and installation mock-ups.

Technology: MJP 3D printing – 0.016mm – 0.032mm printing layer. Limiting the model size to the working chamber of the machine.

Materials: Resin

Colouring: Monochrome or painted models after printing according to the given color scheme.

We invite you to the further part of the article : Part 3 – 3D milling and casting.

Part 3: What are the techniques of making architectural models? Part 3 – milling and casting