MATERIALS

We provide the best quality materials in the printing process

and post-processing. We don’t compromise, we create the best quality product.

We provide the best quality materials in the printing process

and post-processing. We don’t compromise, we create the best quality product.

It consists in applying successive layers of molten thermoplastic onto each other on the print platform. There are many different types of machines operating in this technology. They can be divided by the type of construction (Cartesian, delta), heated table or its absence, the number of heads.

ADVANTAGES

– The cheapest of the available technologies

– Durable materials

DISADVANTAGES

– Fragility of the models

– Laborious curing process

– Weight of the material

APPLICATIONS

– Prototyping

– Artistic prints

– Printouts of characters

– Architectural mock-ups

The technology which is directly based on the SLS. Metal powder distributed by the arm is then sintered along the contour of the model with a high-power laser.

ADVANTAGES

– The toughest of available technologies

– The durability of prints comparable to moldings

– A wide range of metals

– The possibility to produce final components

DISADVANTAGES

– Very high cost of machinery

– Expensive material

APPLICATIONS

– Prototyping

– Production

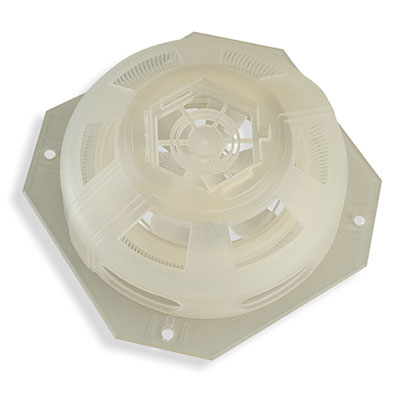

Consists in gradual tracing of the successive horizontal sections of the printed part with the laser on a platform subsequently immersed in a chamber of the photosensitive polymer. It is the only technology in which the timber is in a liquid form in the chamber.

ADVANTAGES

– One of the most accurate technologies

– Best surface finish

– Very high durability

– Wide range of materials with different properties

– Cheap exploitation

DISADVANTAGES

– High cost of machinery

– Requires accurate calibration

– Prints sensitive to UV – yellowing and becoming fragile

APPLICATIONS

– Prototyping

– Production

The SLS technology is similar to the previously discussed CJP technology. The distributing arm puts a layer of powder. Then, the laser beam coks the polyamide powder according to the shape of several layer of the model. SLS machines do not differ from each other too much. Main differences are the sizes of the working chambers.

ADVANTAGES

– No props

– Durable materials

DISADVANTAGES

– High price of equipment and exploitation

– Any unused printing material must be mixed in proportions with the new material

– Rough surface (as compared to Polyjet or SLA)

APPLICATIONS

– Prototyping

– Production

Two names due to a lack of market standards. Existing patents make both Stratasys (Polyjet) and 3D Systems (MJP) promote their names, although the differences are minimal. Polyjet / MJP technology is similar to FDM, except that the head sprays liquid photopolymer on the working table that is cured with UV lamps. There are many different types of machines operating in this technology. The basic division is between machines having heated tables and those that do not have it.

ADVANTAGES

– No props

– Durable materials

DISADVANTAGES

– Long printing time

– Average durability of the models

– Yellowing and becoming fragile when exposed to UV

– The need to leach the support material

– Possibility of deformations

APPLICATION

– Prototyping

By combining materials very accurate dummies of the final products can be printed

– Modeling

It consists in spraying the binder from the heads on the previously distributed layer of gypsum composite. The heads used in this process are the same ones that can be found in inkjet printers. While the printer is printing another layer of the model, the chamber is lowered by the thickness of the layer, and then the arm distributes the building material. The use of inkjet type heads allows printing in color.

After the printing is completed, the powder in which the model is immersed is vacuumed. After removing the model, it is purified from the excess of powder with the use of compressed air. Purified model is cured with one of several hardeners.

ADVANTAGES

– The cheapest of professional technologies

– The fastest 3D printing technology

– 6 million colors

– Complex geometries

– Easy treatment of the prints

DISADVANTAGES

– Long printing time

– Geometry limitations

– High risk of failure

APPLICATIONS

– Production

– Marketing

– Simple 3D printing fun

We provide the best quality materials in the 3D printing process.

We don’t compromise, we create the best quality product.

The strength, flexibility, ease of processing, or the maximum level of details of the forthcoming model are determined not only by the printers used – the materials used for 3D printing also play an extremely important role in this matter. Depending on the order, the ABS plastic is used which is characterized by high hardness and flexibility, the PLA plastic made of renewable raw materials or Visijet PXL, providing an accurate reproduction of details, as well as excellent color saturation. Acura and ABS 3650 give smooth and highly detailed parts for prototypes.

Our new materials PA and CL20 provide high end production parts in short runs.

Description

Visijet PXL material is a high quality powder material used for 3D printing CJP (Color Jet Printing). By using a high quality product such as VisiJet material of a minimum weight, the models are definitely more accurate, whiter and have higher color saturation. Chemical composition: calcium sulphate hemihydrate, CaSO4 * 1/2 H2O, combined gypsum variety of water-based adhesive and cured with three kinds of substances

Specification

Advantages

Description

PLA – polylactic acid, is a biodegradable, thermoplastic polyester produced from renewable, raw materials -it’s called bioplastic. In terms of properties, PLA is similar to polystyrene, but, when modified, has properties similar to polypropylene and polyethylene. It has excellent organoleptic properties and is ideal for food contact. Its properties are similar to those of the ABS, but it is more brittle.

Specification

Advantages

Description

ABS (i.e., acrylonitrile – butadiene – styrene) is a material obtained in the process of polymerization of butadiene and copolymerization of acrylonitrile and styrene with the simultaneous vaccination of the resulting copolymer on the polybutadiene. It is used in industry, in the production of housings of electronic equipment, household appliances, automotive interior parts, sports equipment, or items of furniture. ABS is the material from which panels are produced with excellent impact strength over a wide temperature range. Characterized by high hardness, flexibility, low weight and resistance to scratches. Moreover, it is a readily thermoformable material, having good insulation properties and good chemical resistance.

Specification

Advantages

Description

VisiJet Proplast material with the characteristics similar to plastic, offers numerous functions for various applications in precise prototypes.

Specification

Advantages

Description

Specification

Advantages

Description

Laser- merged, powdery material, with a durability similar to materials made of injection molds, allows you to create ready-made pieces, short production series and articles of jewellery.

PA:

Specification

Advantages

Description

CL 20ES is an austenitic stainless steel for the production of functional parts or components for pre-production moulds.

Specification

Advantages

Rapid Crafting – Materia Sp. z o.o.

Hubska 44F

50-502 Wrocław

tel: +48 692 462 339

info@rapidcrafting.com