Once again we had the pleasure to prepare statuettes for Eurobuild magazine.

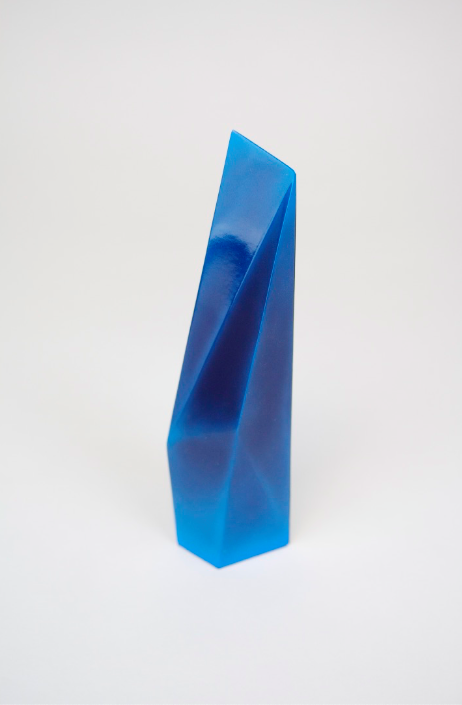

We had only a few weeks for the project. During the project, our task was to design the statuettes, to obtain a modern block in the colors accompanying the event.

After creating a few sketches, we refined the 3D model, which was 3D printed on a 3D printer in the FDM technology. 3D printing definitely speeds up the design process, and technology such as FDM allows us to produce test models at a very low cost.

The model from 3D printing was post-processed in order to resemble the final model as much as possible.

We had 32 statuettes to make, each of which weighed about 600g at a height of about 30 cm. 3D printing was too expensive, so the models were made of cast resin.

We made the appropriate silicone forms and selected a quick bonding resin. This made it possible to cast several models a day.

Each model was varnished and then received a plate made of photo-etched copper.

The end result is very good and the deadline was not threatened in any way by the use of different production technologies.

We would like to congratulate all the winners.