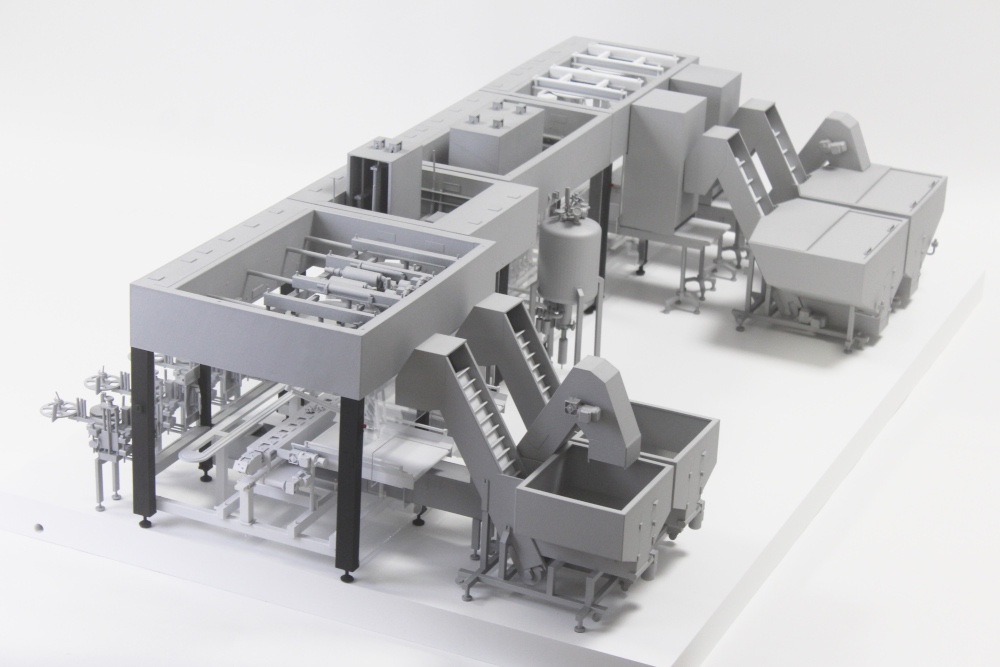

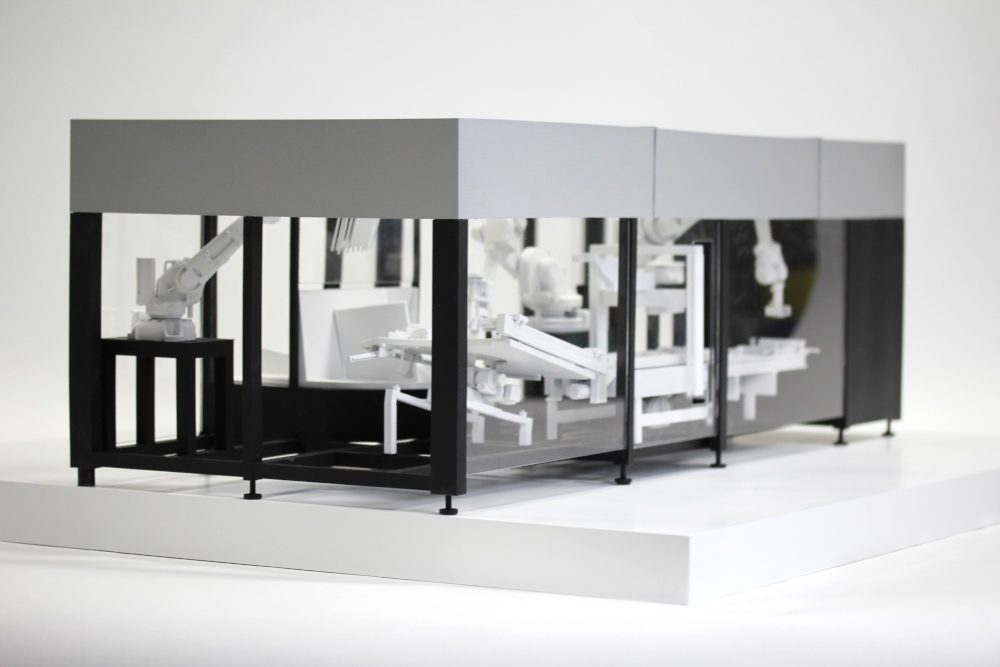

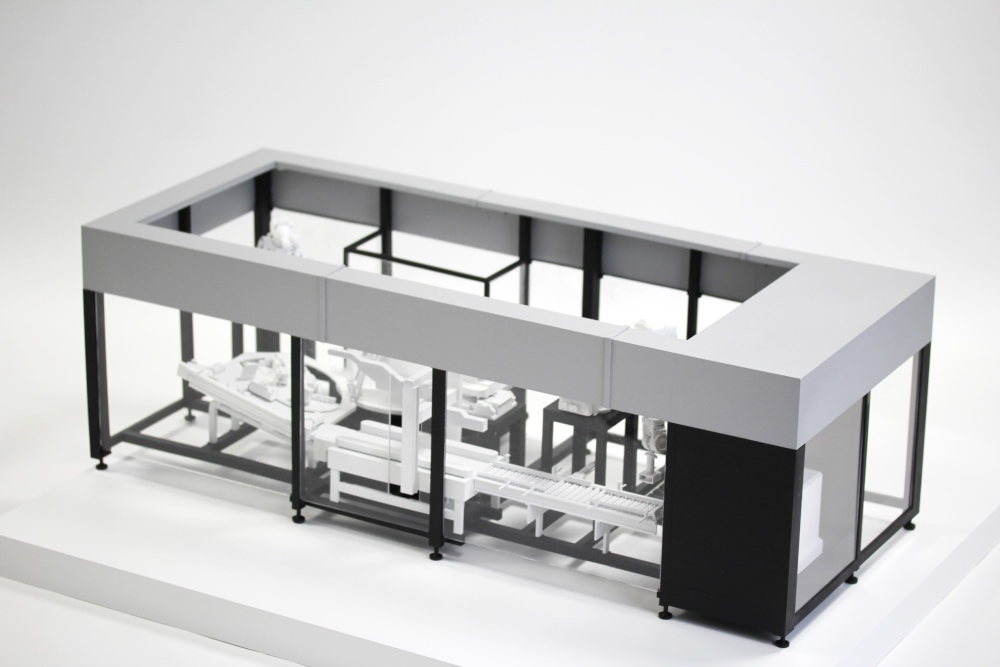

Packaging line for Unilogo

Recently we had the pleasure of making a prototype of a production line for Unilogo, a company that creates specialized packaging machines.

In view of the upcoming trade fair, we had only 2 weeks to do all the work related to the creation of two mock-ups.

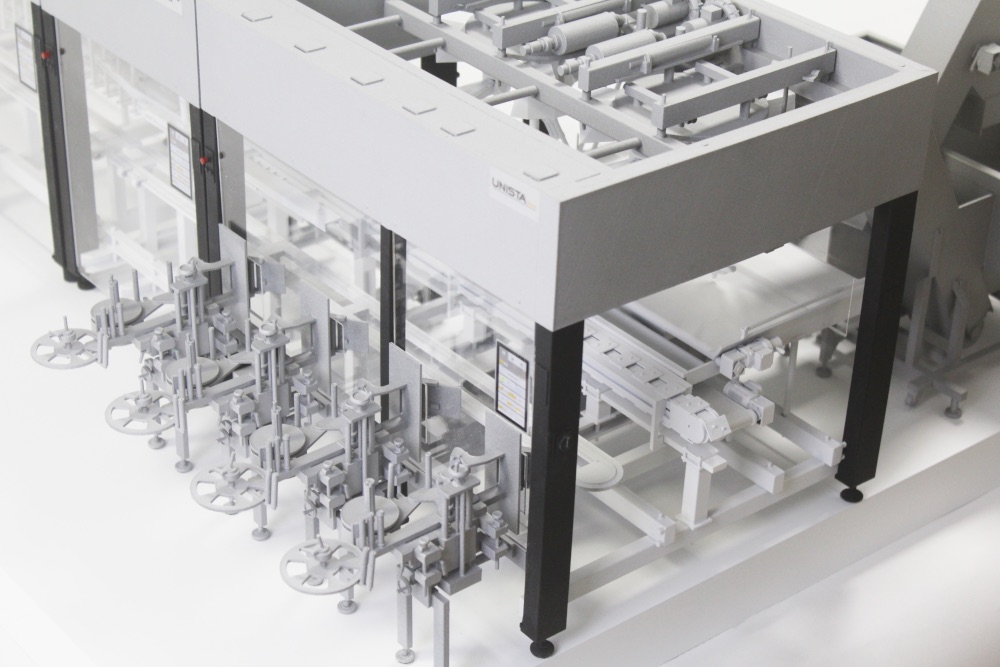

We decided to do them in 3D printing technology. Therefore, the work started with adapting the models supplied by Unilogo in the form of STEP models. Thanks to our qualified staff, we were able to quickly adapt the modules to 3D printing on an appropriate scale.

The models were printed in 3D using MJF (multi jet fusion) technology offered by HP. 3D printouts were printed very quickly due to the 3D printing process offered by MJF technology.

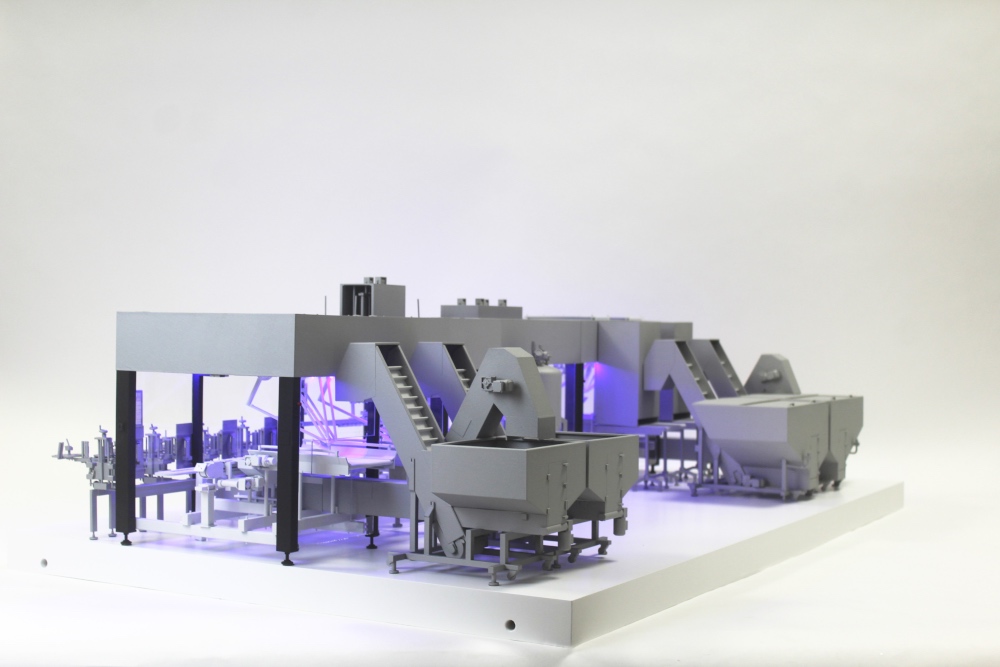

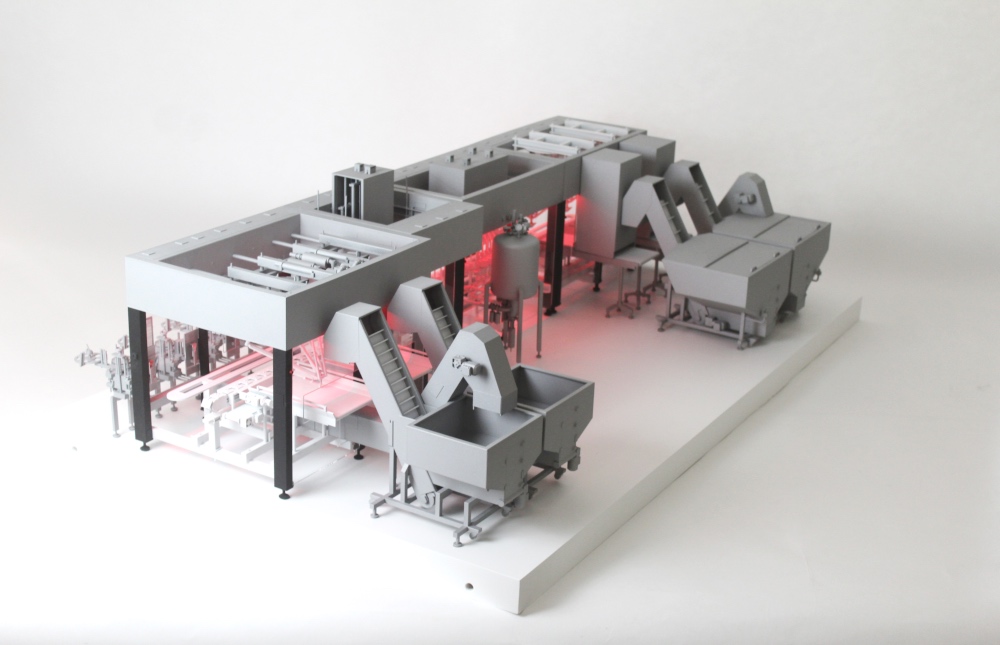

After careful planning, the models were painted and then assembled together with the LED installation.

After 2 weeks we had a ready-made exhibition model, which looked great.