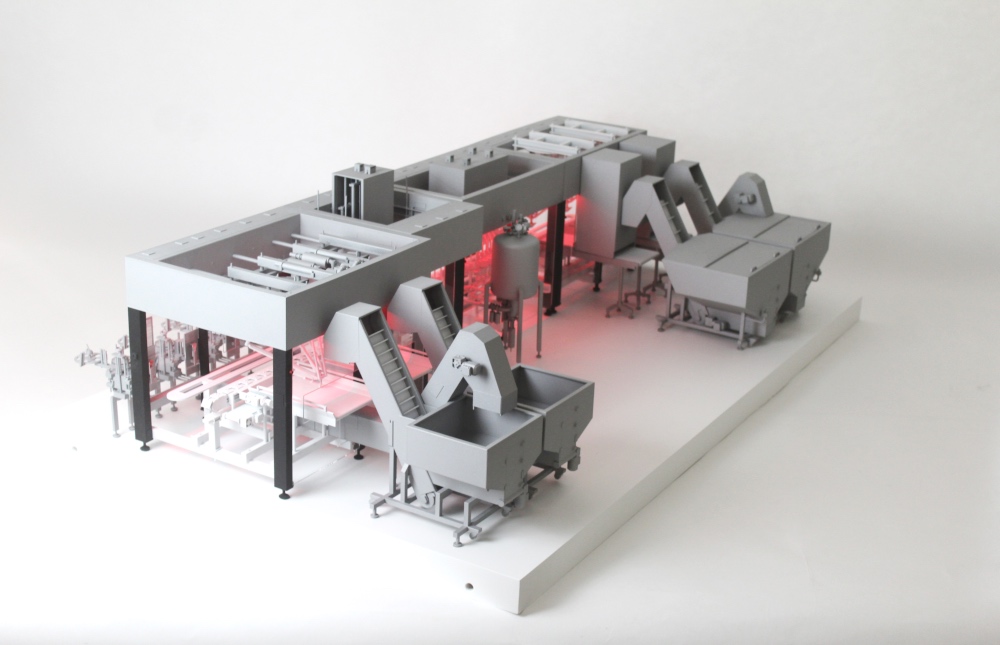

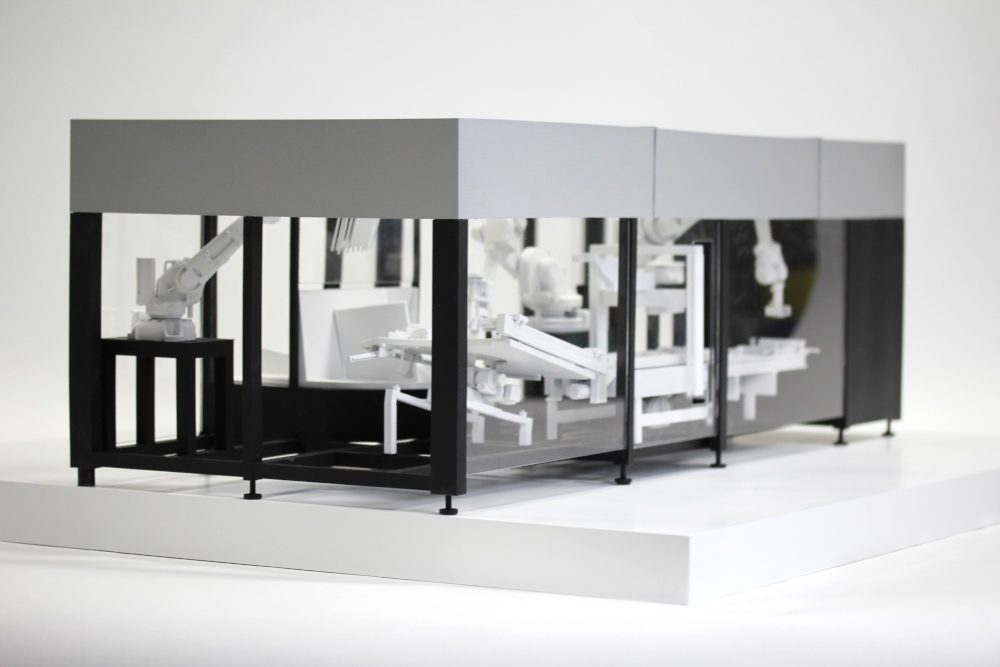

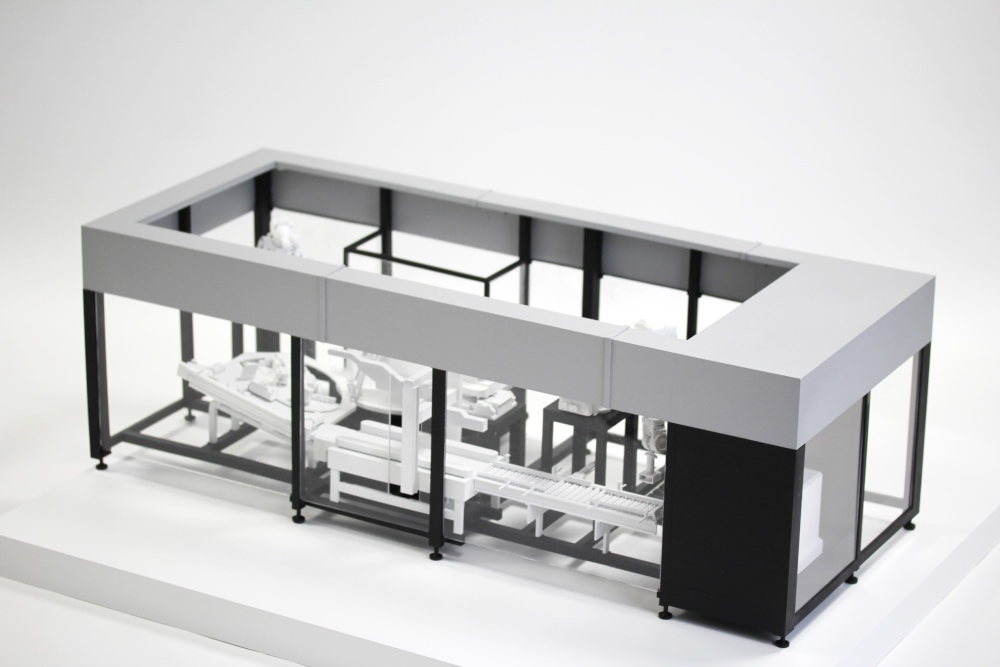

In August this year we were contacted by the international company Kingspan. A manufacturer of many modern solutions for the construction industry.

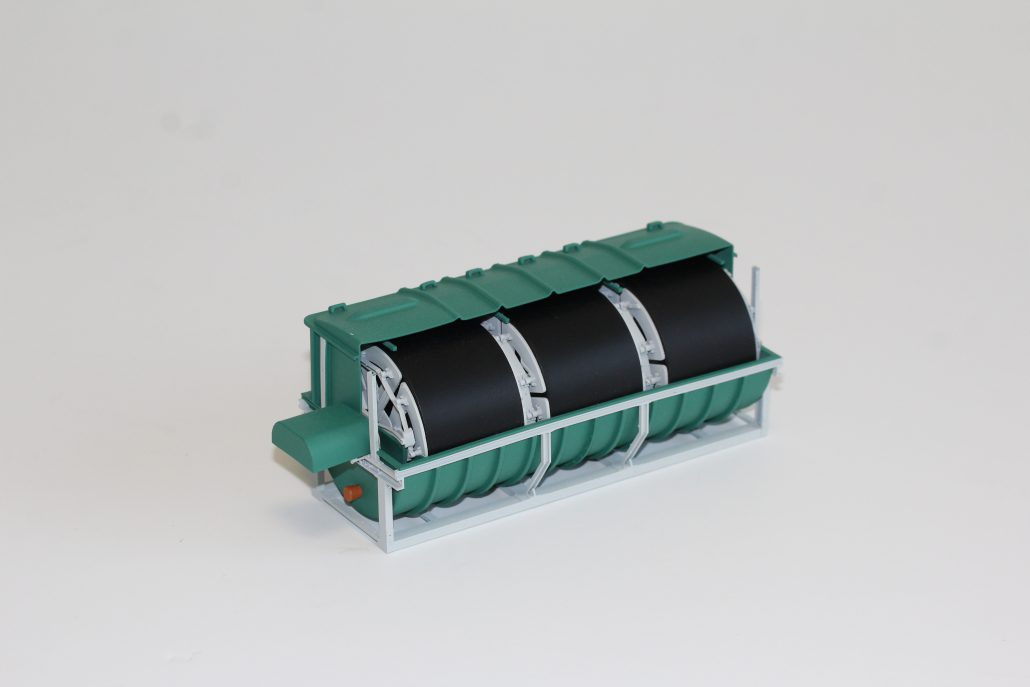

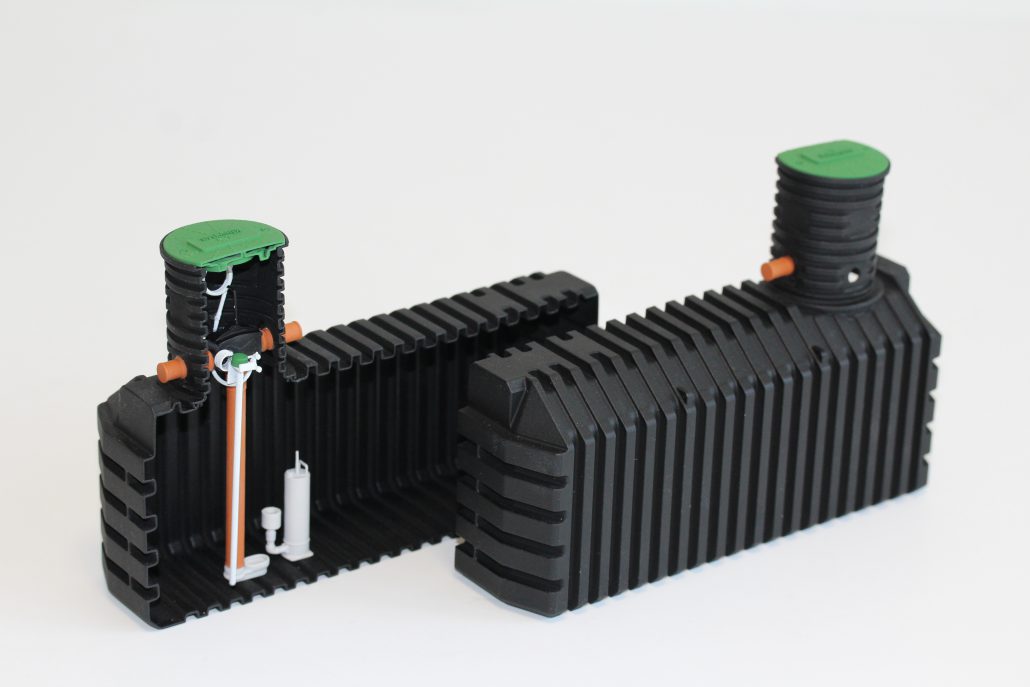

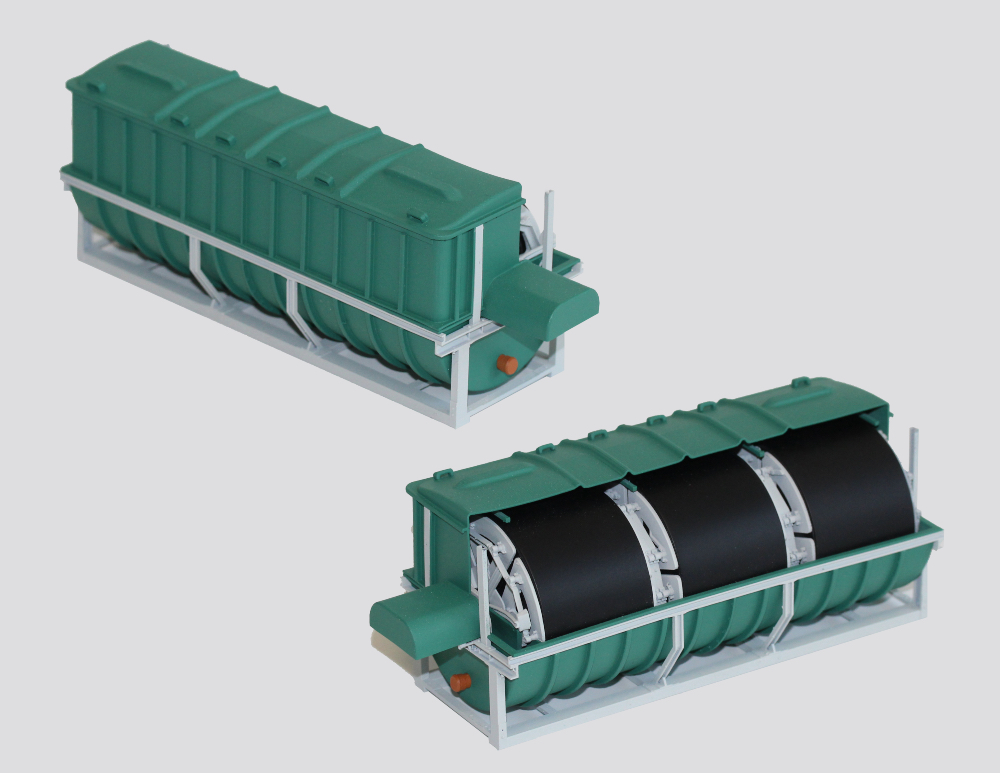

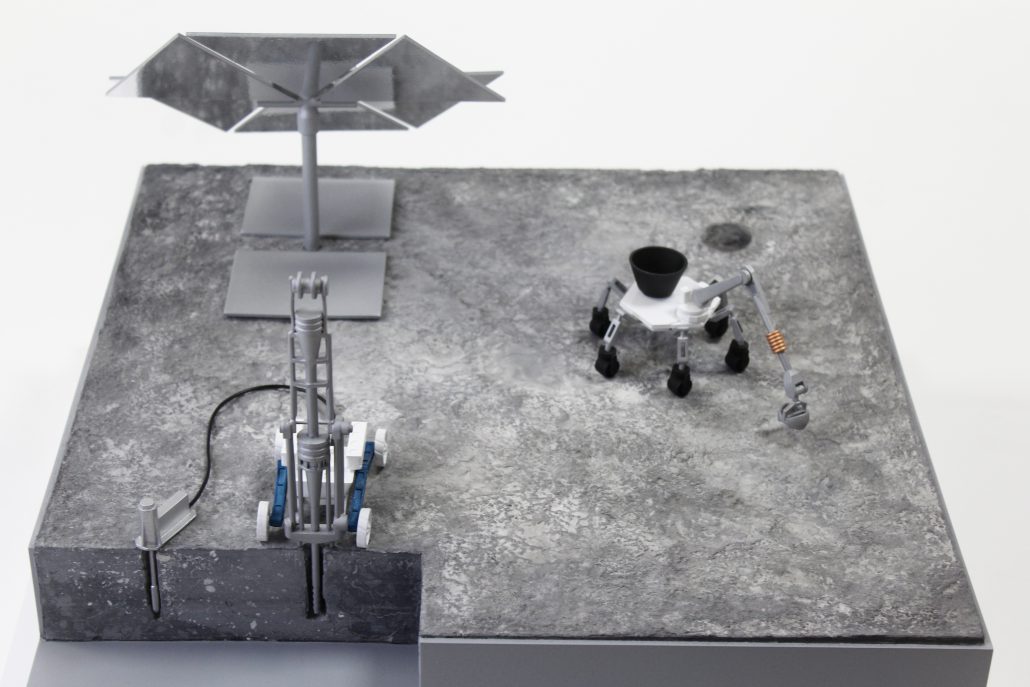

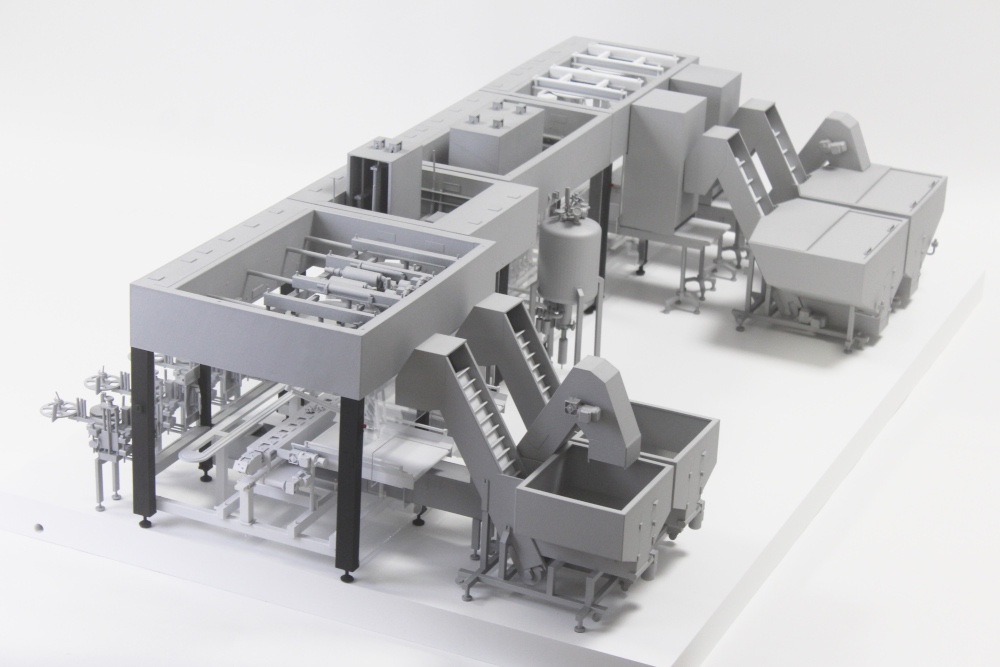

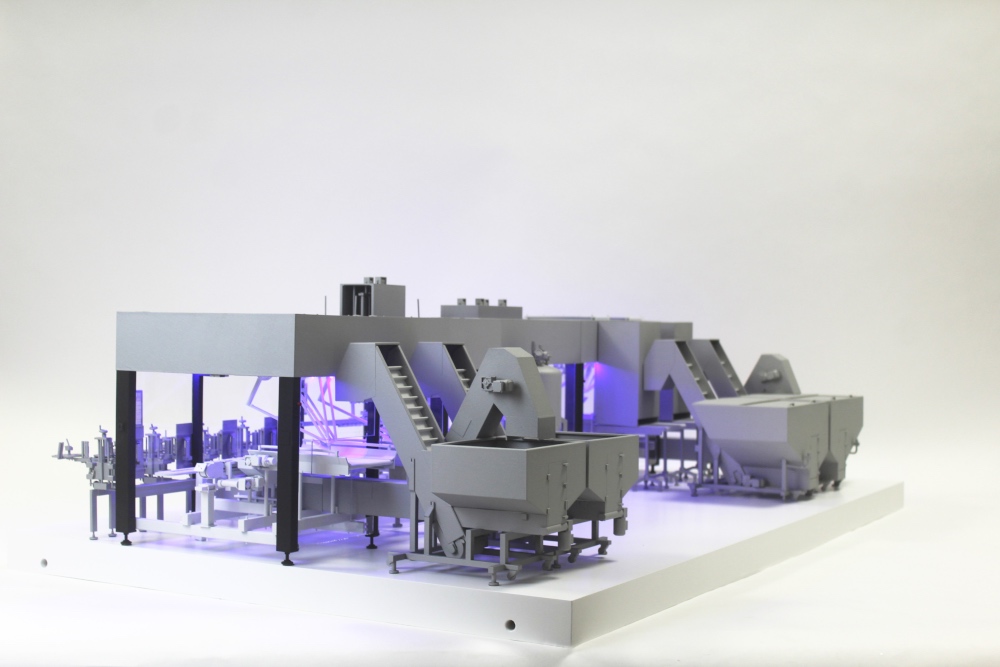

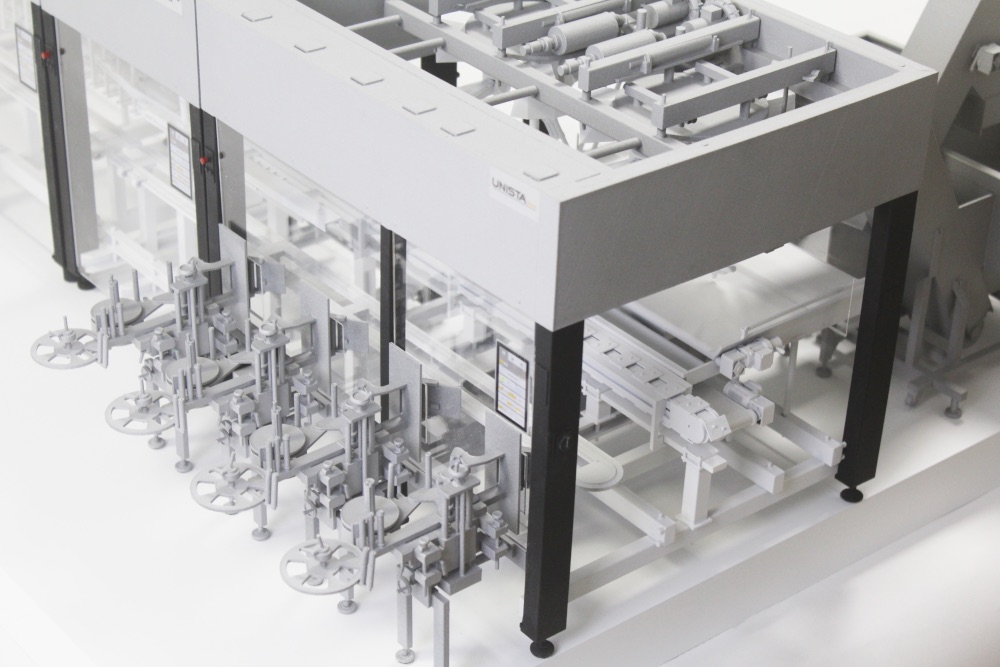

The project included prototypes of a water tank and a commercial mini sewage treatment plant.

The project was different from the others that we made. The task was to make really small and small models (up to 15 cm long). The models are to be used as an element of the installation with the use of photorealistic models and a hologram.

Our models were first redesigned on the basis of the CAD documentation provided to significantly reduce their scale, but with as many details as possible. After receiving the 3D models, we started to print in 3D.

In the production process we used 3D SLA (stereolithography) printing technology, thanks to which each element was precise and almost perfectly smooth.

The models were painted and assembled by our specialists, giving a very good final result.